High power protection for extreme working conditions

In developing PowerGuard® Engineered Yarns, Culimeta-Saveguard has set new standards of comfort for wearers of personal protection apparel.

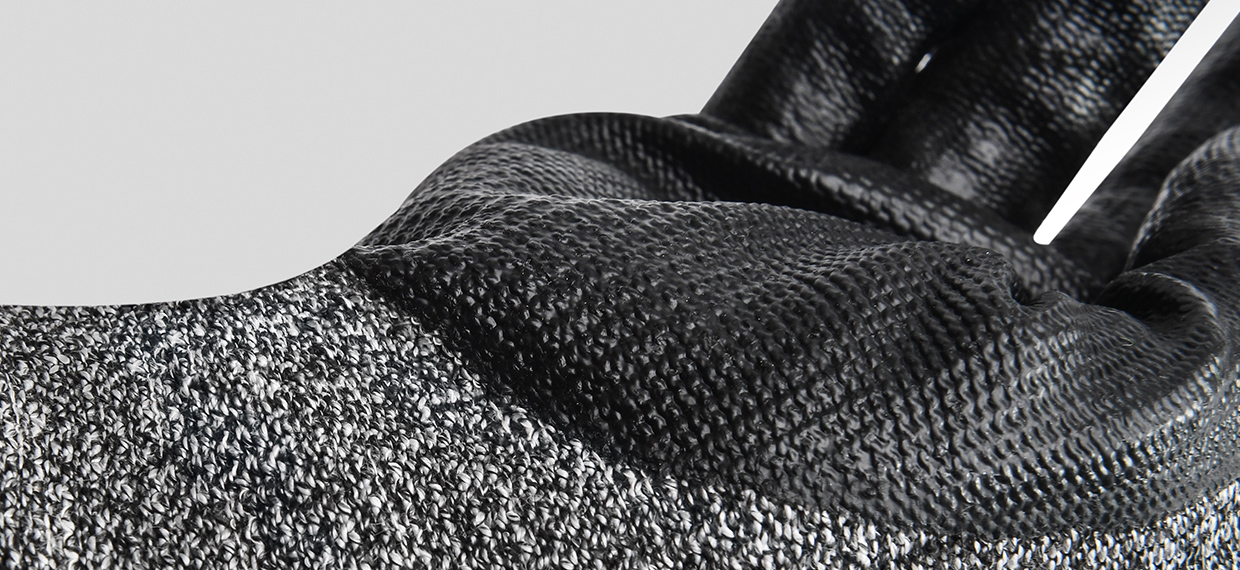

PowerGuard® Engineered Yarns provide the highest cut and abrasion protection possible for personnel protective equipment (PPE).

PowerGuard®Engineered Yarns are ideal for knitting and weaving to create soft, comfortable, tactile, cut and abrasion resistant gloves, sleeves and garments.

PowerGuard® Engineered Yarns contain high performance synthetic materials, including UMWPE, Nylon, Polyester, PEEK, p-Aramid, m-Aramid, ModAcrylic, m-Imid Amide and Ceramic Fibre.

Details

PowerGuard® Engineered Yarns are made at both our UK and Indian sites, using a variety of manufacturing processes, many of which are unique to Culimeta-Saveguard.

Some PowerGuard® Engineered Yarns are manufactured using a bespoke drafting and twisting process that allows fine filaments of wire, textile-grade glass fibres or other high performing filaments to be included.

This process increases the yarn’s cut resistant properties beyond Level 5 (EN 388) in very thin yarns used on GG18 and GG22 knitting machines.

Advantages

- A vast range of counts offer solutions to gloves knitted on GG5 through to GG22

- Highest levels of cut resistance, up to Level F (ISO 13997)

- Soft, flexible, non-itchy, tactile and sensitive – these yarns provide the safest most comfortable gloves available

- Manufactured and assured by a stringent total quality management system, which has TDM ISO 13997 in-process testing.

Want to know more?

If you’re looking for further information, please get in touch – we’d be happy to discuss your project’s requirements in detail.

+44 (0)161 344 2484

sales@culimeta-saveguard.com