THE MOST EFFECTIVE ENGINEERED MUFFLER PACKAGING SOLUTION

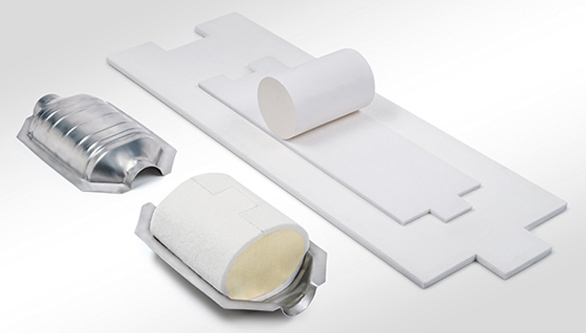

Our Knitted Products use only highly texturised glassfibre yarn made from continuous filament fibre. These are made into a non-woven textile utilising a unique processing technology.

The construction provides a range of technical characteristics including:

- A choice of fibre chemistry offering temperature resistance up to 850oC.

- A range of densities to suit muffler production and end application.

- Compression release (expansion) of the material on initial heating to ensure maximum homogeneous fibre distribution within the chamber or void.

Our Knitted Products are now the acoustic packing solution of choice for some of the most internationally renowned manufacturers of specialist sports car and motorcycle mufflers, for both OEM and after-market.

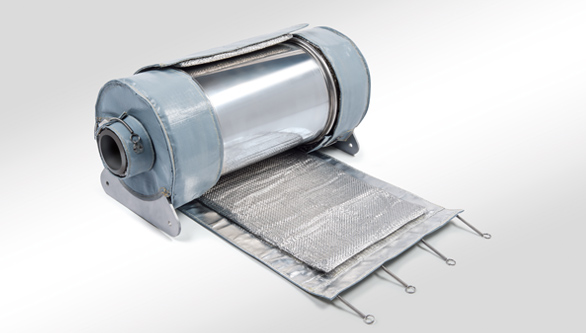

Our Knitted Products have excellent thermal properties and ability to expand when heated make it the ideal solution for insulating between the twin skins of emission control systems, particularly where there is potential for gas flow over the fibres.

Advantages

- Reduces muffler assembly times, providing production efficiencies.

- Engineered product accuracy enhances client quality control and provides controlled fill densities.

- 3D shaped packs available for applications with complex geometries.

- Proven superior resistance to high pulse energies.

- ‘Expands’ to fill voids on heating.

- Provides excellent thermal insulation to reduce hot spots and the need for additional heat shielding.

- Low fibre migration and erosion.

Contact us to discuss your requirements in more detail.

Want to know more?

If you’re looking for further information, please get in touch – we’d be happy to discuss your project’s requirements in detail.

+44 (0)161 344 2484

sales@culimeta-saveguard.com